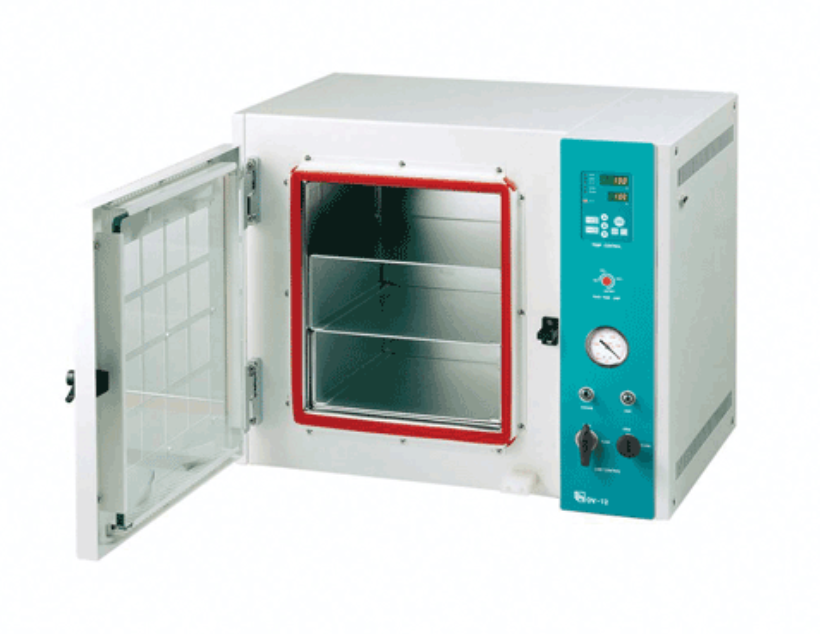

• Temperature range ambient from +5°C to +250°C

• Vacuum Range: 0 to 0.1MPa (analogue vacuum gauge). Drying a solvent in vacuum lowers its boiling point, thereby making the separation process easier and eliminating the need to use high temperatures

• Microprocessor PID control / temperature / calibration / automatic tuning

• Uniform heat distribution from block type heater directly to the anodised aluminium shelves

he TDP 6s v2 is a single punch desktop format tablet press that is based on the highly popular TDP 5, but featuring an upgraded drive mechanism, a more powerful motor, and greater maximum pressure. The TDP 6s can also produce the largest tablets of the TDP range, with a maximum diameter of 25 mm.

-Unique to the R-215 is the addition of a vapor temperature and rotation speed display!

-PTFE composite vacuum seal for long service life and effective sealing

-Space-saving modular design lets you add integrated vacuum controllers and run preset time/pressure gradients

-Motorized, quick-action servo-jack raises and lowers glassware effortlessly

-Wide-range, PTFE-coated 4L heating bath, model B-491, with digital temperature display, uses oil or water, 20 to 180°C (68 to 356°F)

-Enhanced safety: insulated heating bath, Plastic-coated glassware, and optional remote control and safety shield

-Process samples from 50 mL to 3 L

OTF-1200X-S is a compact split tube furnace with a max. the working temperature of 1200°C. The furnace can be adopted either a 1", 2" or 2.36"(60mm) O.D quartz tube (optional) with a pair of stainless steel vacuum sealing flanges wich allows heating samples in the vacuum or flowing gas. The built-in precision temperature controller can provide up to 30 segments of heating and cooling steps with +/- 1 °C accuracy.

200kg include furnace body, metal tube, gas flow controller box and accessories

220V, 3 phases, 58A, 22kW

This WaveDriver® series bipotentiostat/galvanostat is a versatile dual-electrode electrochemical workstation available in a variety of configurations Under the control of our powerful AfterMath® software package, the WaveDriver 200 EIS Bipotentiostat/Galvanostat is capable of performing Electrochemical Impedance Spectroscopy (EIS) along with a wide variety of single and dual electrode DC electroanalytical techniques. The WaveDriver 200 is a true integrated bipotentiostat, capable of controlling one or two working electrodes operating in the same electrochemical cell along with a counter and reference electrode, making this instrument ideal for Rotating Ring-Disk Electrode (RRDE) voltammetry.

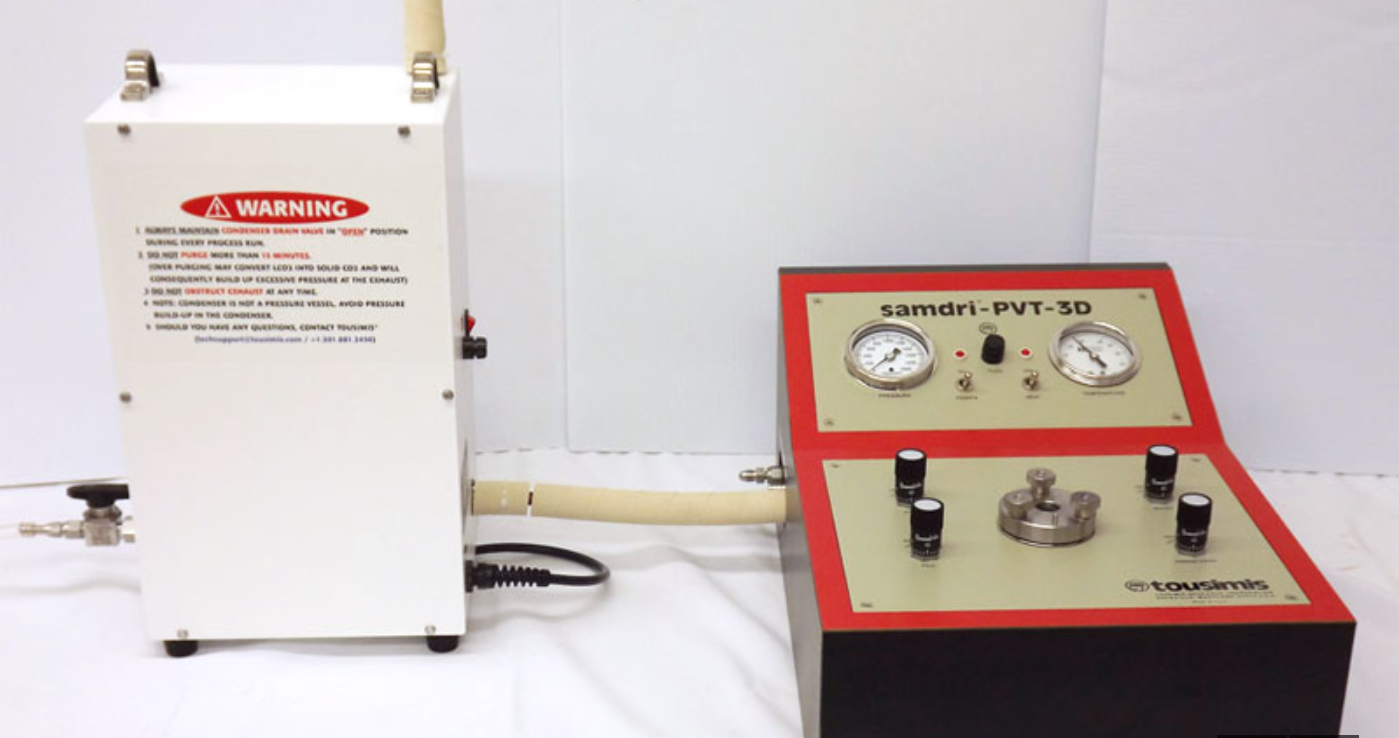

The SAMDRI®-PVT-3D provides high precision results using manual controls. The four Micro-Metering Valves are conveniently located on top of this critical point dryer for ease of operator control. Automatic safety controls are standard features incorporated within the SAMDRI®-PVT-3D.

S/N B951810520

12V, 2.25A

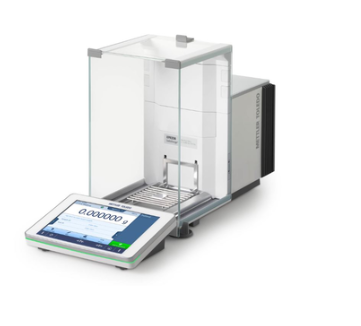

Ma. 220g, d=0.01mg

NOSCE Corporation is a spin-off company from our lab that specializes in sustainable energy solutions. Their flagship product, NiMoCat, is a revolutionary catalyst that enables the conversion of any carbon source, including biomass, plastics, and waste, into synthesis gas (syngas) using renewable energy sources. The syngas is then converted into zero carbon methanol, which can be used in engines and boilers without emitting any CO₂.

The company's syngas economy plan envisions renewables as the core energy supply for producing zero carbon fuels based on CO₂. This sustainable energy solution is designed to enable a smooth transition from fossil fuels to renewable energy sources without breaking the bank. NOSCE's innovative technology is expected to play a significant role in reducing carbon emissions and creating a more environmentally friendly and sustainable future.

NOSCE Corporation's mission is to provide cutting-edge and cost-effective energy solutions that support the transition towards a sustainable future. The company is committed to driving innovation, collaboration, and sustainable practices to make a positive impact on the environment and society.

For more information, please visit www.nosce.us

Metal Capture Corporation is a startup spun off from our lab that is a leading provider of precious metal recovery solutions. The company's technology is based on cutting-edge research findings in the field of urban mining of precious metals from electronic waste, such as printed circuit boards (PCB). While PCBs contain a significant amount of precious metals, their recovery is not yet feasible due to the lengthy isolation process, health risks, and environmental impact.

Metal Capture Corporation's breakthrough technology involves the use of a porous porphyrin polymer that captures precious metals quantitatively from PCB leachate, even in the presence of 63 elements from the Periodic Table. The nanoporous polymer is synthesized in two steps from widely available monomers without the need for costly catalysts and can be scaled up without loss of activity.

Through a reductive capture mechanism, the technology developed by Metal Capture Corporation enables the recovery of gold with 10 times the theoretical limit, reaching a record 1.62 g/g. With 99% uptake taking place in the first 30 minutes, the metal adsorbed to the porous polymer can be desorbed rapidly and reused for repetitive batches.

Metal Capture Corporation's innovative technology is designed to reduce the environmental impact of urban mining and provide a cost-effective solution for precious metal recovery. The company is committed to driving innovation and sustainable practices to make a positive impact on the environment and society. Their technology has the potential to transform the precious metal recovery industry and promote a more sustainable and circular economy.

For more information, please visit www.metalcapture.com

Atilhan Laboratory

Looking forward to creating value with you